Panizzi Eugenio SNC (MURANO, Venezia, ITALY)

THE BEGINNINGS

Panizzi Eugenio was born in Murano in 1960. The founder, Eugenio, born in Grandate in Como in 1922, had begun his work experiences at the age of 11, in a moleria in the area, learning the various grinding techniques.

After the Second World War, in the early 50s, Eugenio arrived in Murano where he joined his brother-in-law Marco Varisco, also master molatore, who had recently opened a moleria. At the time, the company was mainly working on behalf of the Livellara factory, a leading company in the production of crystal objects, which settled in Murano in the post-war period in the area of the Murano Counties, right in front of the moleria headquarters.

The main processes that were made were engravings and grindings such as Bohemia, on glasses, jugs, bottles, plates, table products in general and for lighting.

THE 1960S AND 1970S

In 1960 Eugenio took over the grinding from his brother-in-law Marco, who had since moved to Treviso, and began his activity as “PANIZZI EUGENIO”, a company specialized in the grinding and artistic engraving of bohemia-type glass and crystals, products highly sought after by customers all over the world. Right from the start Eugenio focuses on quality and attention to detail. These attentions will remain over time, and are still the peculiar characteristics of the company.

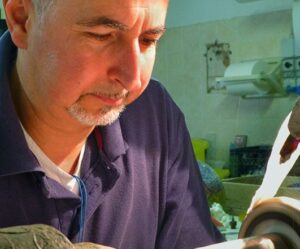

In the 1970s his son Mauro began working with Eugenio who, following the teachings of his father, managed to learn the secrets of traditional grinding and engraving, essential elements for the formation of a master grinder to be complete. A few years later his son Franco also began to attend his father’s grinding machine, learning the various techniques of craftsmanship.

FROM THE 1980S TO THE PRESENT DAY

In 1985 Franco and Mauro joined the company that will be called “PANIZZI EUGENIO & C. SNC”, giving new life to the activity and, thanks to the introduction of new projects, integrate and modify some production lines, adapting the products to new customer requests.

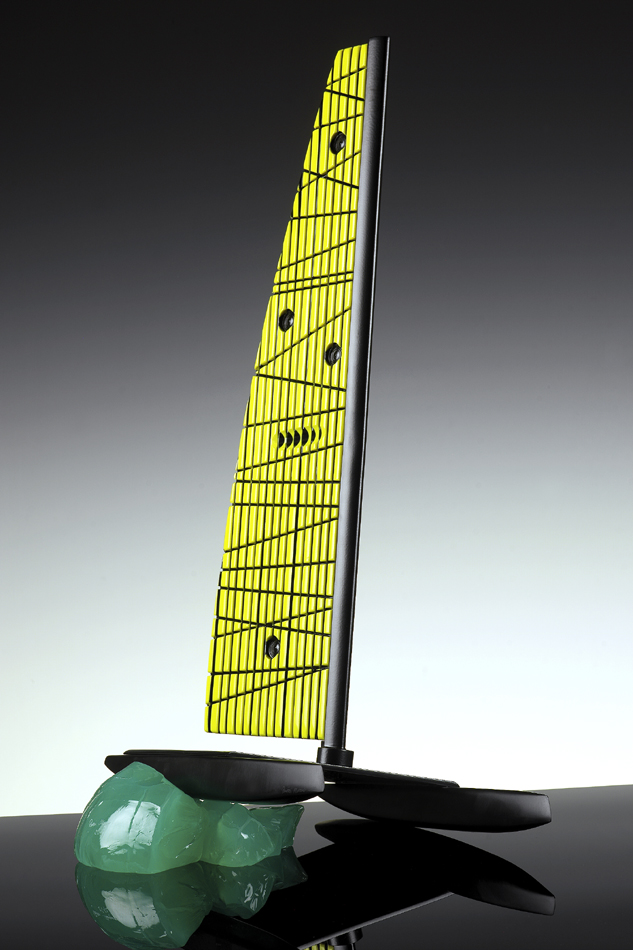

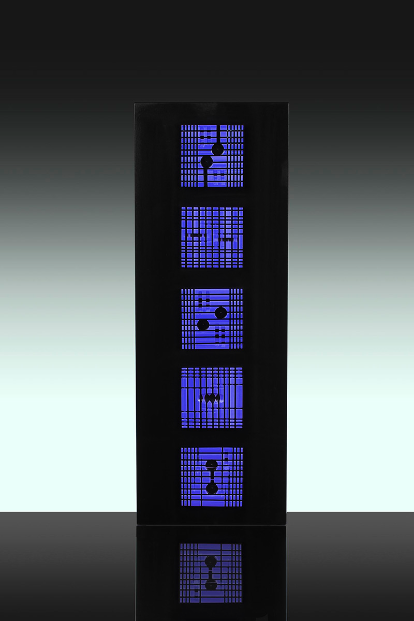

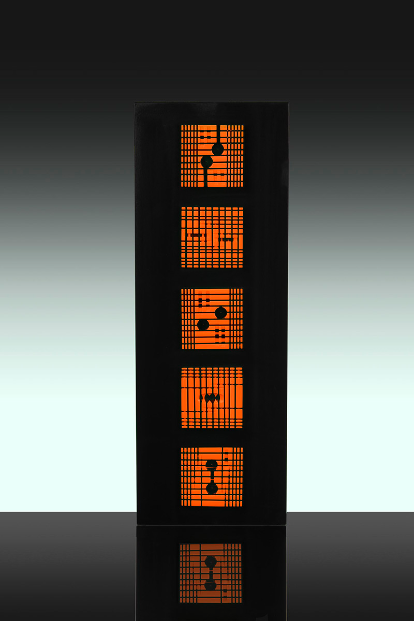

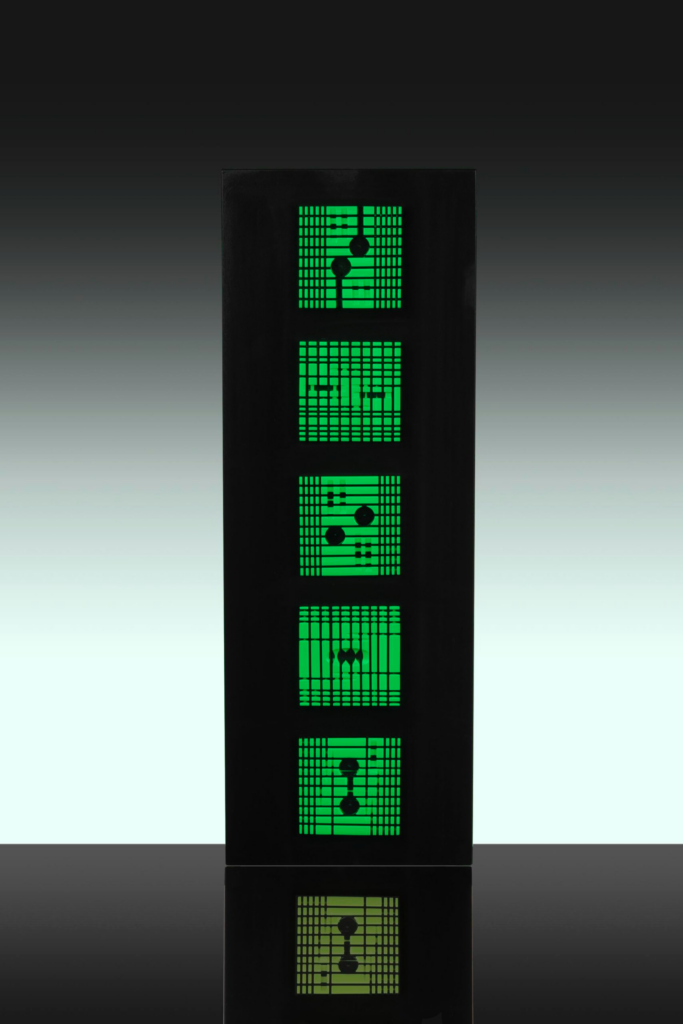

Relevant for their growth was the year 1994 which saw the installation of furnaces for the melting of glass (in technical language “fusing”); at the same time they attend a specialized course in glass design, at the Murano Glass Study Center.

The production immediately assumes characteristic traits, differentiating itself from the usual Murano production. Based on these innovations, the unique products take on the captivating lines that an increasingly conscious and demanding clientele required. In this sense, a show-room is opened, adjacent to the laboratory, to present to the public all the objects of the production line.

TECHNIQUE

GRINDING

Grinding is a technique, in use for many years, which allows the glass to be “dug” and which is carried out in several stages: a coarse-grained silicon carbide wheel is used; then one of the same finest grain material; a natural sandstone wheel that removes the rough marks; another a fourth cork wheel impregnated with a mixture of pumice stone powder and water, useful for polishing glass. Finally, cleaning with a cloth wheel soaked in cerium oxide and water and abundant rinsing in running water.

BEATING

The “beaten” glass is characterised by a stained surface not evenly, but in order to have countless small round slightly irregular signs (notches), adjacent and sometimes parallel to each other. In performing this technique, the master engraver, with an appropriate roughness wheel, affects the surface with dense and regular, rounded or oblong engravings, in order to remove the brilliance of the glossy glass to create opaque areas with a pleasant tactile effect. This technique, typically Murano, dates back to the 1930s.

INCISION

The engraving of the glass, is carried out with a roll of abrasive stone (it can be of various diameters and different grains, depending on the type of engraved sign you want to make); it can also be made of metal (bronze) with a manatee surface. The current engraving of glass, finds its origin in the engraving of hard stones that was carried out, with splendid results, in Germany and Bohemia in the seventeenth century. At the end of that period it was also introduced in Venice, with the arrival of German engravers, in the cold processing (or second processing) of Murano glass.

MELTING GLASS

It is a very ancient technique, which also includes mosaic glass. Currently it is carried out using sections of glass of different colours, which are cold-juxtaposed, on a ceramic fiber plate, and fused into an electric oven in order to obtain a layer of multicolored vitreous fabric called mosaic glass or murrino glass. On the slab are arranged torn or glass granules of different colors that blend with the basic glass support. The operation can be repeated several times by overlapping the colors or layers, sometimes creating a three-dimensional décor

While continuing to use traditional working methods, we want to combine the techniques of grinding and typing, fusing and blasting, in a perfect symbiosis of ancient taste and modern design.